Get Hands-On SAP PM Experience with Online Training

- 30 Hrs Instructor-led Training

- Mock Interview Session

- Project Work & Exercises

- Flexible Schedule

- 24 x 7 Lifetime Support & Access

- Certification and Job Assistance

- Basic Knowledge of SAP

- Technical Background

- Relevant Industry Experience

- Knowledge of Maintenance Processes

- Communication Skills

- Good Communication Skills

- Digital Transformation

- Industry-Specific Solutions

- Integration with Other SAP Modules

- Continued Development

The fee for SAP PM(Plant Maintenance) training can vary depending on several factors such as the location, duration of the course, training format, and level of expertise. SAP offers various training options for PM, including instructor-led courses, e-learning courses, and virtual live classrooms.

For More details you can Register

SAP PM(Plant Maintenance) Certification FAQ's:

1. What is SAP PM Certification?

A: SAP PM Certification is an internationally recognized certification that validates an individual's expertise in SAP Plant Maintenance. It demonstrates that the person has the necessary knowledge and skills to manage the maintenance of plants in an organization using SAP software.

2. What are the prerequisites for SAP PM Certification?

A: To be eligible for SAP PM Certification, you must have a minimum of two years of practical experience in SAP Plant Maintenance or related fields. Additionally, you must have a solid understanding of the basic concepts of SAP Plant Maintenance.

3. What is the exam format for SAP PM Certification?

A: The SAP PM Certification exam consists of 80 multiple-choice questions that you must answer within three hours. The exam covers various topics, including equipment and technical objects, work order management, preventive maintenance, and corrective maintenance.

4. What is the passing score for SAP PM Certification?

A: The passing score for SAP PM Certification is 60%. This means you must correctly answer at least 48 of the 80 questions.

5. How long is SAP PM Certification valid?

A: SAP PM Certification is valid for two years. After that, you must recertify to maintain your certification status.

6. What are the benefits of SAP PM Certification?

A: SAP PM Certification can help you advance your career by demonstrating your expertise in SAP Plant Maintenance. It can also enhance your credibility with employers, increase your earning potential, and give you access to a global community of SAP professionals.

7. How can I prepare for SAP PM Certification?

A: To prepare for SAP PM Certification, you can take training courses, study online resources, and practice with sample questions. You can also join a study group or attend SAP events to network with other professionals and gain additional insights.

8. What are the topics covered in the SAP PM Certification exam?

A: The SAP PM Certification exam covers various topics related to SAP Plant Maintenance, including:

Technical Objects and Equipment Master Data

Preventive Maintenance Planning

Maintenance Order Management

Maintenance Processing

Maintenance Project Management

Corrective Maintenance

Maintenance Reporting and Analysis

9. Can I retake the SAP PM Certification exam if I fail?

A: Yes, you can retake the SAP PM Certification exam if you fail. However, you must wait for 14 days before you can retake the exam.

A: Yes, SAP PM Certification is recognized globally as a standard for validating an individual's expertise in SAP Plant Maintenance. It is recognized by companies and organizations worldwide as a reliable measure of a person's skills and knowledge in this field.

SAP PM(Plant Maintenance) Certification:

SAP PM (Plant Maintenance) certification is a professional certification offered by SAP SE, a leading provider of enterprise software solutions. This certification validates the candidate's knowledge and skills in the SAP PM module, which covers various aspects of plant maintenance, including equipment maintenance, maintenance planning, work order management, and preventive maintenance.

To obtain SAP PM certification, candidates need to fulfill certain eligibility criteria, including having relevant work experience and completing the required training courses. They also need to pass the SAP PM certification exam, which is conducted by SAP SE.

The SAP PM certification exam is a computer-based exam that consists of multiple-choice questions. The exam duration is three hours, and candidates need to score at least 64% to pass the exam. The exam fee varies depending on the country and region where it is taken.

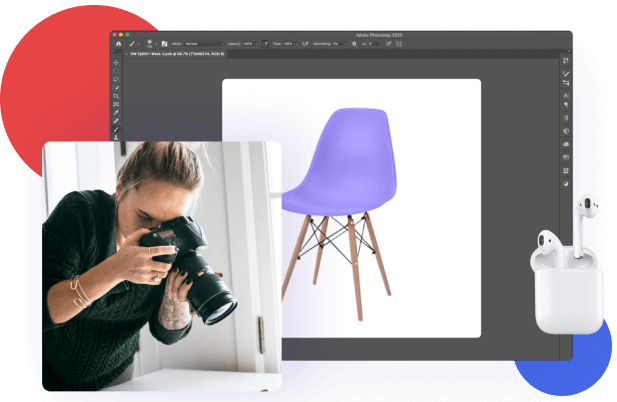

Participants will have 24/7 access to our online lab, providing hands-on experience with SAP PM tools and scenarios.

This includes server access to S/4 HANA 2023 for 1 year, ensuring you have ample time to practice and apply your skills in a real-world environment.

With this extended access, you can work on projects, explore advanced features, and solidify your understanding of SAP PM in the latest SAP S/4 HANA version.